.jpg) |

|

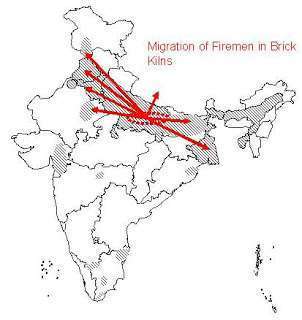

Migration of Firemen with the majority being from Uttar Pradesh.

|

.jpg) |

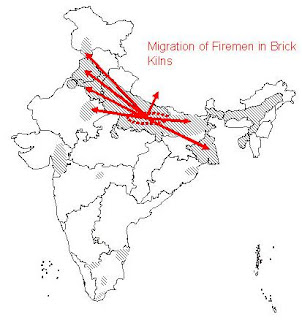

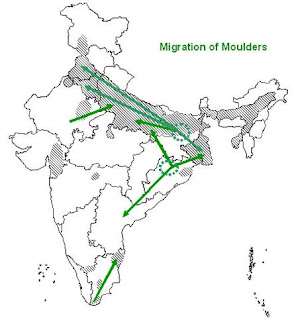

| Migration of Moulders |

- Clamp

- Intermittent Kiln

- Hoffman Kiln

- Bull trench Kiln

Quality Tests

Presently, we’re conducting quality tests on these Bricks. These tests not only require a lot of precision in the process, but also observation.

- Compression Test

- Absorption Test

|

- Technological Support: Graduate the current structure with minimum investment to form better quality low cost bricks.

- Financial Support: Small Brick producers can be extended some sort of financial help through financial institution loan linkages.

- Environmental Friendly Bricks: The Bricks industry is always under the Government scrutiny for environmental reasons, so if the Kilns get some support to produce environment friendly bricks, the Kilns will have improved and efficient production.